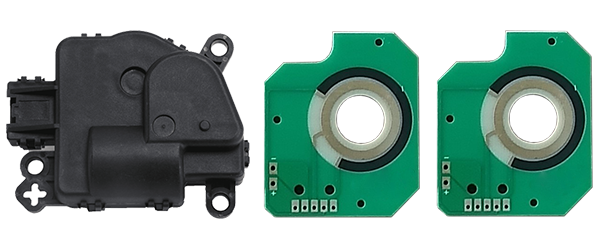

HVAC Blend Door Actuator PCB

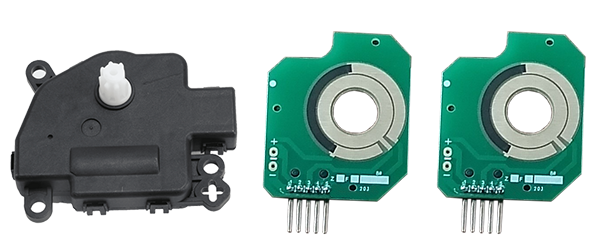

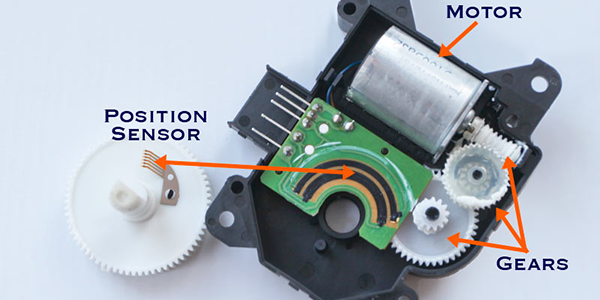

HVAC Blend Door Actuator PCBs, also called as HVAC Heater Blend Door Actuator PCBs, regulate the temperature inside automobile cabins to ensure the comfort of both drivers and passengers by controlling the position of the air blend doors within the HVAC (Heating, Ventilation, and Air Conditioning) system, and are typically manufactured using thick-film resistor technology, which guarantees stable electrical performance and high precision.

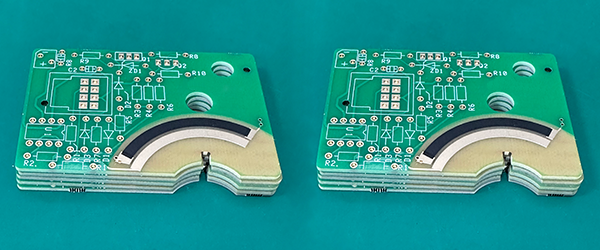

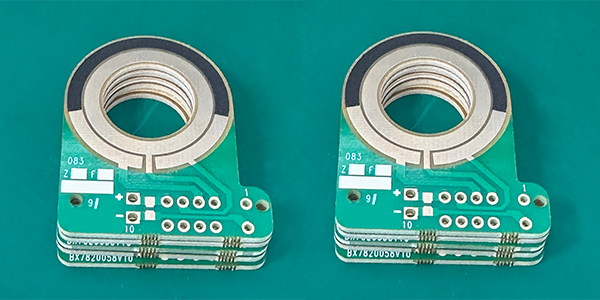

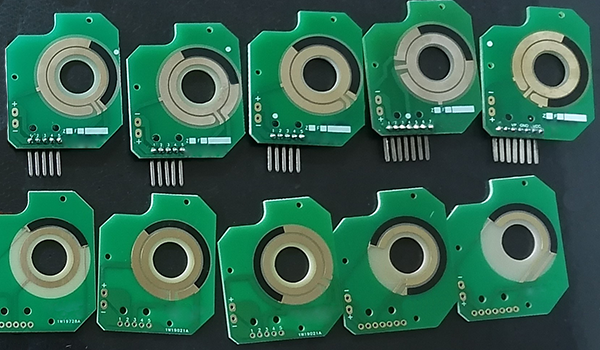

HVAC Blend Door Actuator PCBs utilize thick-film resistor technology. Thick-film resistors are directly printed onto the PCB surface using a silk-screening technique, followed by high-temperature sintering to achieve greater stability and precision. This process ensures the product's long-term reliability and durability, allowing it to function efficiently in the complex automotive environment. The manufacturing of these PCBs also includes additional integration layers and process controls to ensure the circuits meet automotive standards.

HVAC Blend Door Actuator PCBs adjust the opening and closing of the air blend doors by controlling the resistance of a potentiometer (adjustable resistor). The resistance value of the potentiometer changes as the position of the air door changes, providing feedback to the control system. This feedback adjusts the proportion of hot and cold air to maintain precise temperature control. Designed for automotive use, these PCBs must be highly reliable and accurate to manage the dynamic changes in vehicle temperature regulation. They also need to withstand high working temperatures and vibrations, ensuring stable long-term performance.

HVAC Heater Blend Door Actuator PCBs are characterized by high precision, reliability, and longevity. The thick-film resistor technology used in these PCBs allows them to operate stably in high-temperature and high-vibration environments, while also providing excellent anti-interference capability. These PCBs can precisely control the position of the air blend doors, ensuring accurate and reliable temperature regulation within the cabin. Additionally, their adjustable resistor design enables efficient temperature control, meeting the stringent demands of modern automotive temperature regulation systems.

Why Linearity Matters in HVAC Blend Door Actuator PCBs ?

HVAC Blend Door Actuator PCBs play a crucial role in regulating temperature and airflow within automobile HVAC systems. The linearity of HVAC Blend Door Actuator PCBs is an important factor that directly impacts the precision and efficiency of these systems. Linearity refers to how the position of the air blend door corresponds to the control signal or input voltage. The importance of linearity in HVAC Blend Door Actuator PCBs can be understood in the following ways:

● Precise Temperature Control: Accurate temperature regulation relies on maintaining a predictable and proportionate relationship between the input signal and the actuator's movement. When the HVAC Blend Door Actuator PCB is linear, small changes in the input signal will result in proportional changes in the position of the blend door. This helps to achieve precise temperature adjustments, ensuring that the cabin temperature is maintained at the desired level with minimal fluctuation.

● Comfortable Driving Experience: A HVAC Blend Door Actuator PCB with high linearity ensures that air distribution inside the cabin is consistent. Non-linear systems can cause uneven airflow, leading to areas of the cabin being too hot or too cold. This disrupts comfort, especially in situations requiring rapid temperature adjustments. A linear actuator ensures a smoother and more responsive temperature control experience for both the driver and passengers.

● Energy Efficiency: Systems with higher linearity are more efficient at regulating temperature and airflow, reducing the need for excessive power consumption to adjust the blend door position. This leads to better fuel efficiency and lower energy usage in hybrid or electric vehicles, as the HVAC system can adjust more precisely without using unnecessary power.

● Reduced Wear and Tear: HVAC Blend Door Actuator PCBs that operate with high linearity ensure smoother actuator movements, reducing mechanical stress. This can prolong the lifespan of both the actuator and the HVAC system as a whole, resulting in fewer maintenance issues and lower long-term costs for vehicle owners.

● Enhanced System Performance: The precision in controlling the air blend doors enables better integration with other systems in the vehicle, such as cabin air quality control, humidity management, and defrosting mechanisms. High linearity ensures that these features operate in harmony, improving the overall efficiency and functionality of the HVAC system.

The linearity of HVAC Blend Door Actuator PCBs is critical for ensuring efficient, reliable, and precise temperature and airflow regulation within a vehicle's HVAC system. It enhances the comfort, performance, and energy efficiency of the vehicle, making it an essential feature in modern automotive design.

HVAC Blend Door Actuator PCB Design Considerations :

When designing HVAC Blend Door Actuator PCBs, several important factors must be considered to ensure the efficient and reliable operation of the system. These factors help optimize performance, energy efficiency, and durability in automotive HVAC applications. Key design considerations include:

1. Linearity: Linearity is critical for accurate temperature control. The PCB must ensure that the actuator’s movement is proportional to the input signal, allowing for precise adjustments in the blend door position. This helps maintain stable cabin temperature and airflow, enhancing overall comfort.

2. Signal Integrity: HVAC Blend Door Actuator PCB must be designed to handle high-frequency signals without introducing noise or interference, which could compromise the actuator’s accuracy and performance. Ensuring clear and stable signal transmission is essential for reliable operation.

3. Temperature Range: Automotive environments expose HVAC systems to extreme temperature fluctuations. The PCB must be designed to operate within a wide temperature range, typically from -40°C to 125°C, to ensure durability in both hot and cold conditions.

4. Size and Form Factor: Space in vehicles is limited, so the PCB design must be compact and fit within the actuator housing without compromising functionality. A smaller form factor is often needed without sacrificing performance or reliability.

5. Power Consumption: Efficient power management is crucial, especially for hybrid and electric vehicles. The PCB should consume minimal power while maintaining the ability to accurately control the actuator. Low power consumption helps improve overall vehicle efficiency and reduces the load on the vehicle’s power system.

6. Durability and Reliability: HVAC systems are subjected to vibration, moisture, and other environmental factors. HVAC Blend Door Actuator PCB should be designed with durable materials and coatings to resist corrosion, wear, and damage from these factors. High reliability is essential to minimize system failures and maintenance costs.

7. Signal Processing and Control: The design should incorporate advanced signal processing and control circuits to accurately drive the actuator based on input from temperature sensors or control modules. The PCB should also allow for fault detection to ensure that any issues with the actuator or HVAC system can be quickly identified and addressed.

8. Electromagnetic Compatibility (EMC): HVAC Blend Door Actuator PCB design must meet electromagnetic compatibility standards to prevent interference with other electronic systems in the vehicle. Proper shielding and grounding techniques should be used to reduce electromagnetic emissions and susceptibility.

9. Material Selection: The choice of materials for both the PCB itself and its components is crucial for long-term reliability. Materials FR4 or ceramic must be resistant to temperature extremes, moisture, and vibration, while also being compatible with automotive manufacturing processes.

Designing HVAC Blend Door Actuator PCBs requires careful consideration of factors such as linearity, size, durability, and power consumption. These elements must work together to create a system that is reliable, efficient, and capable of performing well under the demanding conditions of modern vehicles. Effective PCB design ensures smooth operation of HVAC systems, improving the driving experience and energy efficiency in vehicles.

For more information, Please refer to Thick Film Potentiometer PCB.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB