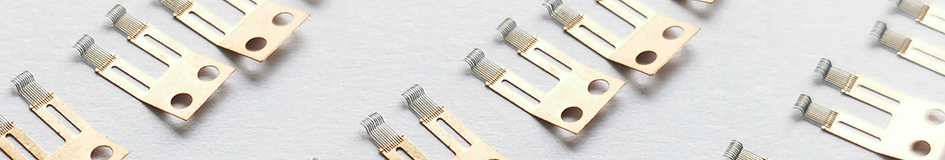

Multi-Wire Wipers

Multi-Wire Wipers, also known as Multi-Contact Wipers, are electrical contact elements widely used for reliable signal transmission in various sensor applications, designed to distribute electrical signals across multiple contact points to ensure high connection reliability, constructed with multiple spring wire contacts that engage with the resistive track of a potentiometer or sensor, allowing for a more uniform distribution of contact pressure and reducing the likelihood of signal degradation over time. Multi-Wire Wipers are typically designed to smoothly slide along conductive tracks or resistive strips, facilitating the reliable transmission of signals in various applications. Contact wipers find significant application in linear potentiometers, linear position sensors, They can be found in a range of systems and mechanical engineering fields, medical technology, and the automotive industry, also they are utilized in gas pedals or throttle valves for enhanced performance and precision. Multi-Contact Wipers can offer better linearity and minimize the effects of temperature variations, ensuring stable and consistent output. A key feature of Multi-Wire Wiper is their design with multiple contacts, which is particularly suitable for linear applications where precision and repeatability are crucial. This makes it suitable for applications where high precision and accuracy are required, such as in scientific instruments, audio equipment, and industrial control systems. |

|

|

|

In a potentiometer, Multi-Wire Wiper is a sliding contact that moves along a resistive element, allowing the user to vary the output voltage or resistance by adjusting the position of the wiper. A multi-wire wiper consists of multiple separate wire contacts that are connected to the wiper arm. When designing the Multi-Wire Wiper, It is very important to consider contact resistance, repeatability, hysteresis, the resistive material used, and in particular, the wiper material itself, its shape and the wiper pressure. Overall, a multi-wire wiper enhances the performance, reliability and longevity of potentiometers, making them valuable components for various electronic applications requiring precise control and measurement of voltage or resistance. |

|

Key Features of Multi-Wire Wipers : |

|

Multi-Wire Wipers offer several key features that make them advantageous for use in potentiometers and other electronic devices. Here are some of the primary features of multi-wire wipers: 1, Improved contact reliability: Multi-wire wipers have multiple separate wire contacts that distribute current across a larger surface area, reducing wear and enhancing electrical performance. This leads to improved contact reliability and reduced contact resistance. 2, Reduced resistance tolerance: The use of multiple wire contacts helps to reduce the overall resistance tolerance of the potentiometer, leading to more accurate and precise readings. 3, Better linearity: Multi-wire wipers can offer better linearity than traditional single-wire wipers, which can help to minimize errors in measurement and control. 4, Temperature compensation: Multi-wire wipers can help to minimize the effects of temperature variations on output voltage or resistance, ensuring stable and consistent performance even in environments with fluctuating temperatures. 5, Higher precision: The improved contact reliability and reduced resistance tolerance of multi-wire wipers help to provide higher precision in measurement and control, making them suitable for use in applications where high accuracy is required. |

Main Types of Multi-Wire Wipers : |

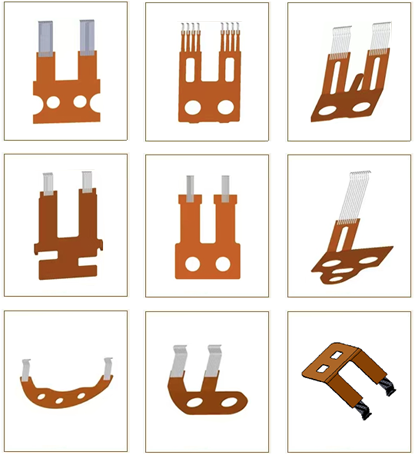

Multi-Wire Wipers are mainly used for potentiometers or position sensors, and its main types can be divided into: |

|

|

1, Spring Metal Multi-Wire Wiper: |

● Manufacturing Process: The Spring Metal Multi-Wire Wiper is based on a spring metal sheet material (i.e., the contact point material is the same as the spring substrate material), which is manufactured through techniques such as laser cutting, stamping, and heat treatment. The spring metal itself can serve as a direct contact material. Its manufacturing process is similar to that of conventional metal stamping processes, transforming a flat metal into specific and desired shapes. Because this type of Multi-Wire Wiper does not require welding other precious metals as contact points, it has become the most common component for sensors due to its high cost-effectiveness, versatility, and sophisticated craftsmanship. |

|

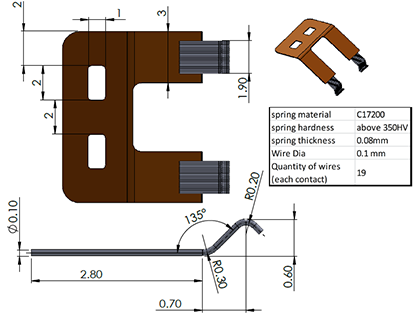

● Spring Materials: C1720, C7701, C1990, commonly used thicknesses are generally 0.05mm, 0.08mm, 0.1mm, etc. ● Features: The main features are simple structure, stable mechanical strength, easy assembly, low production cost, and short production cycle. In addition, to prevent oxidation on the surface of the Spring Metal Multi-Wire Wiper, nickel or gold plating can be applied to the surface of the Multi-Wire Wiper. |

|

|

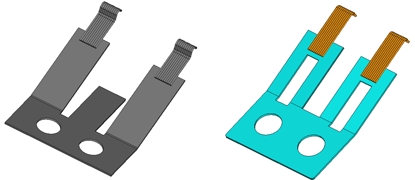

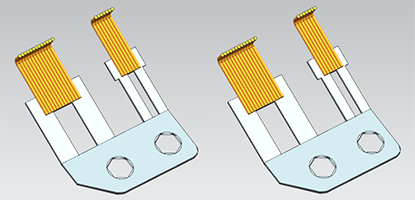

2, Precious Metal Multi-Wire Wiper: |

● Manufacturing Process: Based on the manufacturing foundation of the Spring Metal Multi-Wire Wiper, the Precious Metal Multi-Wire Wiper is created through welding processes (such as resistance welding or laser welding) by precisely welding the filamentous precious metal (Paliney-6) to the spring material to serve as a contact point, forming a higher-performance precious metal Multi-Wire Wiper. Unlike the Spring Metal Multi-Wire Wiper manufactured by stamping technology, the Precious Metal Multi-Wire Wiper can weld up to 30 parallel precious metal alloy wires (Paliney-6) to the spring material, significantly increasing the number of contact points in each contact area. |

|

● Spring Materials: C1720, C7701, C1990, commonly used thicknesses are generally 0.05mm, 0.08mm, 0.1mm, etc. ● Contact Materials: Paliney-6 (Pd, Ag, Cu, Au, Pt, Zn), commonly used alloy wire diameters are generally 0.05mm, 0.08mm, 0.1mm, etc. ● Features: The Precious Metal Multi-Wire Wiper uses an alloy wire with a nickel coating and electromagnetic shielding as a contact point, which has high corrosion resistance, good elasticity (flexibility), and is not easy to scratch the surface of the conductive layer or resistance layer. It can better improve the wear resistance of copper tracks or carbon films. Through welding multiple alloy wires as contact points, it provides optimal electrical contact surfaces and more contact points, effectively improving signal transmission stability and reliability. Correspondingly, the manufacturing cost of this type of Precious Metal Multi-Wire Wiper will be higher than that of the Spring Metal Multi-Wire Wiper. |

|

Specifications of Multi-Wire Wipers : |

Wiper Types |

Wire Materials |

Wire Diameter |

Spring Material |

Spring Thickness |

Carrier (Base) Material |

Carrier (Base) Thickness |

Durability |

Spring Metal Multi-Wire Wiper |

N/A |

N/A |

C1720 (CuBe2), |

0.05mm, 0.08mm, 0.1mm |

C7701-EH, Stainless steel |

0.25mm, 0.3mm, 0.4mm, 0.5mm |

0.5-2 million |

Precious Metal Multi-Wire Wiper |

Paliney-6 |

0.08mm, 0.1mm |

C1720 (CuBe2), |

0.05mm, 0.08mm, 0.1mm |

C7701-EH, Stainless steel |

0.25mm, 0.3mm, 0.4mm, 0.5mm |

2-5 million |

General SPEC |

General Tolerance : +/-0.1mm, Minimum radius : R0.1mm, Unspecified Radius : R0.2mm, Burr max : 0.01mm, Minimum welding strength : min 30N, Minimum Contact spacing : 0.15mm, Minimum Contact width : 0.2mm ; PS : Paliney-6 alloy is composed of 10% gold, 30% silver, 10% platinum, 35% palladium, 14% copper, and 1% zinc ; |

||||||

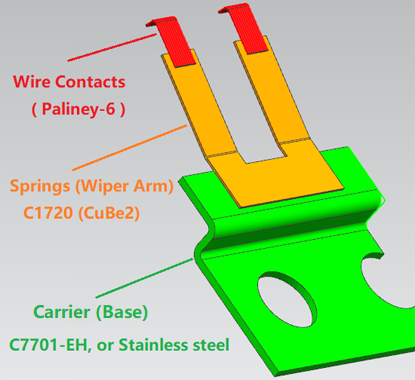

Composition and Structure of Multi-Wire Wipers : |

A Multi-Wire Wiper in the context of a potentiometer refers to the component responsible for making electrical contact with the resistive element within the potentiometer. It is used to vary the resistance and generate a variable voltage or signal output. Here is an overview of the composition and structure of a Multi-Wire Wiper in a potentiometer or position sensor: Composition:● Resistive Element: The potentiometer contains a resistive element, typically made of a conductive material like carbon or conductive plastic. This element is responsible for providing the variable resistance. ● Wiper Assembly: The multi-wire wiper consists of a wiper arm or blade along with multiple wire contacts. These wire contacts are evenly spaced and mounted on the wiper arm. |

|

|

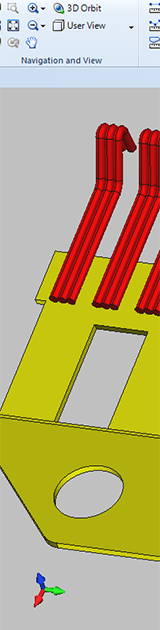

Structure:● Wire Contacts: also known as terminals or contact fingers, are small metal strips or wires mounted on the wiper arm. Contact fingers serve as the points of contact that slide along conductive tracks or resistive strips to reliably transmit signals for the application.They make electrical contact with the resistive element as the wiper arm moves. ● Springs (Wiper Arm): Spring material is utilized to provide contact pressure and maintain mechanical strength for the contact fingers. It may also serve as a carrier for mounting, particularly when the wiper is to be mounted using a hot-press with pin-riveting process. The wiper arm is a movable component that rotates or slides along the resistive element. It is typically attached to a mechanical mechanism, such as a knob or slider, which allows the user to adjust the position of the wiper arm. ● Carriers: The carrier is only utilized for mounting purposes, and the carrier substrate is typically designed with a thickness ranging from 0.2mm to 0.8mm, especially when the wiper is intended to be mounted by screws with rubber padding. |

Advantages of Multi-Wire Wipers : |

1, Enhanced Contact Reliability: The multiple wire design of multi-wire wiper ensures numerous contact points between the wiper and the surface, boosting overall contact reliability for consistent and effective performance. 2, Customizable Contact Force: By individually adjusting the bending angle and spring rate of each wire, multi-wire wipers allow for tailored contact force optimization, ensuring efficient cleaning without surface damage. |

|

|

3, Extended Service Life and Corrosion Resistance: Incorporating precious metals like gold or silver, multi-wire wipers exhibit exceptional corrosion resistance, prolonging service life and sustaining reliable performance in challenging environments. 4, Durable with High Abrasion Resistance: Engineered to endure rigorous use, multi-wire wipers resist abrasion effectively, capable of lasting a minimum of 3 million cycles (potentially up to 5 million cycles), reducing maintenance needs and costs. 5, Reliable in Extreme Temperatures: Designed to function reliably in temperatures from -40 to +250°C, multi-wire wipers maintain operational efficiency across varying environmental conditions, ensuring dependable performance in diverse industries and applications. 6, Reduced Maintenance Requirements: Due to their durability and long service life, multi-wire wipers help reduce maintenance requirements, resulting in cost savings and increased operational efficiency. |

7, Enhanced Cleaning Performance: The design of multi-wire wiper allows for thorough and efficient cleaning, ensuring that surfaces are effectively cleared of debris, contaminants, or other unwanted substances. 8, Versatility in Application: Multi-wire wipers are versatile and can be used in a variety of industries and applications, thanks to their customizable contact force and reliability in different environmental conditions. |

|

Applications of Multi-Contact Wipers : |

1, Diverse Applications: Multi-Contact Wipers are employed in diverse applications such as robotics, medical equipment, military and defense, renewable energy, and power generation due to their durability, precision, and ability to withstand harsh environmental conditions. 2, Automotive Technology: Within automotive technology, multi-contact wipers function as vital contact elements in fuel gauges, oil pressure indicators, and position transmitters for butterfly valves, steering wheels, accelerator pedals, and gear levers, enabling crucial operational feedback and control in vehicle systems. |

|

|

3, Industrial Automation: In the field of industrial automation, multi-contact wipers can be utilized in various mechanical and electrical systems to enable precise control and feedback. 4, Position Indication: Multi-Contact Wipers serve as essential components for position indication in linear or angular position transmitters, commonly referred to as linear position sensors, providing accurate feedback and control in various industrial and automotive applications. 5, Aerospace Industry: Multi-Contact Wipers can be used in sensors and control systems in aircraft and spacecraft to ensure precise electrical connections and operational feedback. 6, Dynamic Electrical Systems: Contact wipers play a key role in facilitating the transmission of signals between moving parts in slip ring systems and small DC motors, ensuring continuous and reliable connectivity in dynamic electrical systems. |

7, Communication Equipment: In communication equipment, multi-contact wipers can be employed to ensure signal transmission and electrical connectivity between various moving parts, maintaining stability and reliability of the devices. 8, Measurement and Control Technology: In the field of measurement and control technology, multi-contact wipers are utilized in rotating, sliding, and trimming potentiometers, also known as linear potentiometers, to ensure precise and reliable electrical contact. 9, Medical Devices: Multi-Contact Wipers can also find applications in medical devices such as surgical equipment and monitoring instruments, ensuring proper functioning and accurate data feedback. |

|

Welding Techniques of Multi-Wire Wipers : |

Resistance Welding and Laser Welding have different approaches when it comes to the welding process for Multi-Wire Wiper. Here below to show you what are the differences between these two welding techniques for Multi-Wire Wipers: ● Resistance Welding Technique: ● Laser Welding Technique: Here below to compare the differences in the welding process for Multi-Wire Wipers using these two techniques: |

|

|

1, Heat Input And Control: ● Laser welding: Laser welding offers precise control over the heat input as the laser beam can be accurately focused on the welding area. The heat-affected zone can be minimized, reducing the risk of overheating or distortion of the Multi-Wire Wipers. 2, Weld Quality And Strength: ● Laser welding: Laser welding can produce high-quality welds with minimal defects. The precise control over the heat input and narrow heat-affected zone contribute to clean and aesthetically pleasing welds. The strength of laser-welded Multi-Wire Wipers depends on the material properties and proper process parameters. |

3, Welding Speed And Efficiency: ● Laser welding: Laser welding can also be a fast and efficient process, especially for thin wires. The focused laser beam allows for rapid and precise heating, enabling high-speed production. |

|

|

4, Flexibility In Welding: ● Laser welding: Laser welding offers greater flexibility in terms of material compatibility and geometry. It can join a wide range of metals, including dissimilar materials, and is suitable for intricate and complex welding of Multi-Wire Wipers. Resistance welding relies on electrical current to generate heat for Multi-Wire Wiper welding, while laser welding utilizes a focused laser beam. Resistance welding provides fast and efficient bonding, while laser welding offers precise heat control and flexibility for various materials and geometries. The choice between these techniques ultimately depends on specific requirements, including the desired weld quality, speed, and material compatibility. |

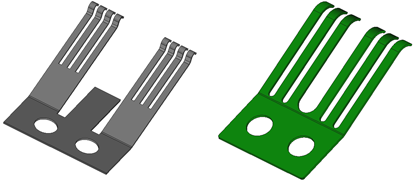

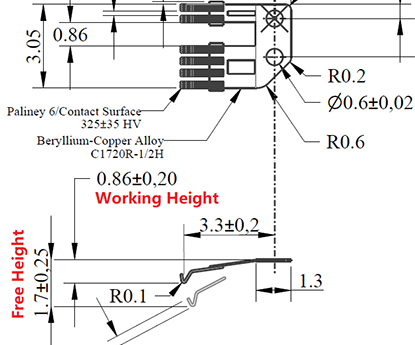

Design Considerations for Working Height of Multi-Wire Wipers : |

● When engineers design a dedicated Multi-Wire Wiper for a potentiometer or position sensor, they need to consider the height of the wiper as a critical key point. |

|

|

● Typically, customers only need to consider the height after assembly when designing the Multi-Wire Wiper, specifically the distance from the wiper substrate to the conductive or resistive tracks. ● Furthermore, if customers require the wiper to achieve a specified pressure after assembly, such as 15cN, they need to inform us of the pressure requirement in advance. We will conduct relevant tests and adjust the manufacturing parameters of the wiper to meet the pressure requirement. |

● In simple terms, when customers provide us with Multi-Wire Wiper drawings (in CAD or STEP format), if there are no specific instructions, We will all default this original height to the height after assembly. |

|

How To Order Multi-Contact Wipers ? |

1, Explore Options: Browse our wide range of Multi-Contact Wiper available in various specifications to suit different application needs. 2, Customization: Tailor the Multi-Contact Wiper to align with your specific application requirements and end product specifications. 3, Submission: Send us your wiper drawing in PDF, CAD, or STP format, or provide a 3D model, along with the necessary specifications for feasibility assessment. |

|

|

4, Feasibility Checking: Our team will review the submitted information to ensure feasibility and compatibility with your requirements. 5, Design Assistance: Benefit from design for manufacturability (DFM) suggestions provided by our team to optimize the production process. 6, Order Placement: Once the details are finalized, proceed to place your order with our assistance and guidance throughout the ordering process. 7, Completion: Sit back and relax as we work on manufacturing your customized Multi-Wire Wiper to meet your specific needs and expectations. |

8, Delivery: Receive your tailored Multi-Wire Wiper and enjoy their enhanced performance in your applications. Experience a seamless and efficient ordering process for your custom Multi-Wire Wiper tailored to your exact specifications. Our team will be glad to provide design for manufacturability (DFM) suggestions and assist you throughout the ordering process. |

|