Quality Policy

Quality Management :

Panda PCB Group holds several key certifications, including ISO 9001:2015, ISO 14001:2015, IATF 16949:2016, UL, ROHS, REACH, and QC 080000:2017. We are fully committed to compliance with all applicable laws and regulations, upholding best practices in quality assurance, environmental protection, occupational health and safety, and corporate social responsibility. Panda PCB is dedicated to continuous improvement to ensure sustainable and stable growth in the long term.

Quality Commitment :

We believe that quality is a reflection of our commercial integrity. We take full responsibility for our unwavering commitment to achieving zero-defect quality, with the goal of enhancing the quality of life for all. Delivering flawless products is vital to meeting and exceeding our clients' expectations. To maintain consistency and drive continuous improvement in our manufacturing processes, Panda PCB Group employs dimensional monitoring throughout production, using qualified inspection instruments guided by Statistical Process Control (SPC).

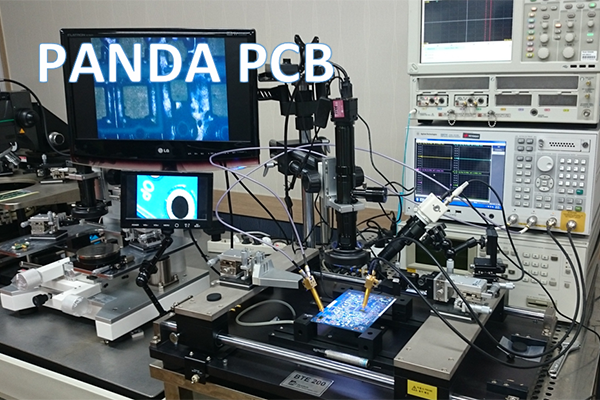

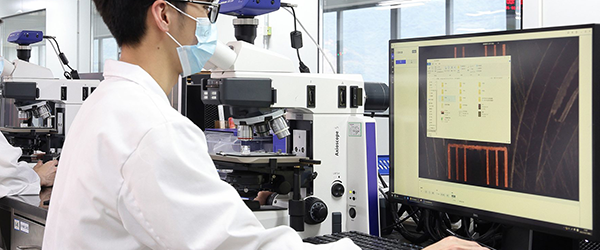

Quality Control :

Panda PCB Group leverages advanced software to perform in-depth Design for Manufacturability (DFM) analysis on incoming data and employs cutting-edge quality control systems throughout the entire manufacturing process. We manage key processes to proactively address potential issues before production begins. To ensure the highest quality standards, Panda PCB Group conducts:

● 100% Automated Optical Inspection (AOI)

● Electrical Testing

● High Voltage Testing

● Impedance Control Testing

● Micro-sectioning

● Thermal Shock Testing

● Solder Testing

● Reliability Testing

● Insulating Resistance Testing

● Final Quality Control (FQC) Ionic Cleanliness Testing

Management Systems :

Management Policy :

● Continuously improve and refine our management system.

● Provide customers with products and services that meet or exceed their expectations.

● Comply with all applicable laws and regulations, and efficiently utilize resources to promote ongoing improvements in product quality and environmental responsibility.

Quality Philosophy :

Panda PCB's quality management is dedicated to ensuring customer confidence in our products and services. We believe that even a 1% defect rate can result in 100% dissatisfaction for our customers. Therefore, we are committed to maintaining impeccable standards throughout all our operations.