Multi-Wire Wipers

What is Multi-Wire Wiper ?

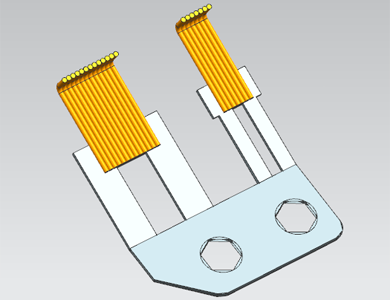

Multi-Wire Wipers also called Multi-Contacts Wipers, are used as contact elements for the reliable transmission of signals in a wide variety of areas. Multi-Wire Wipers is used to slide on conductor tracks in potentiometric applications. The Wiper is designed with multiple contacts particularly suitable for linear applications. By distributing the electrical signal to be transmitted to as many contact points as possible, they guarantee high contact reliability. |

|

||

|

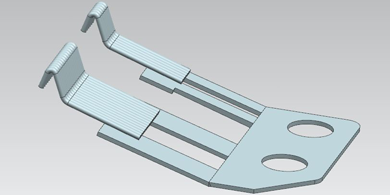

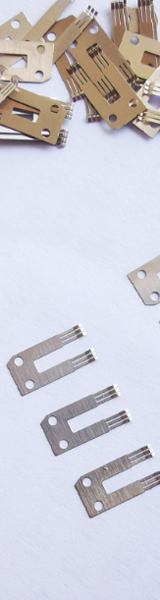

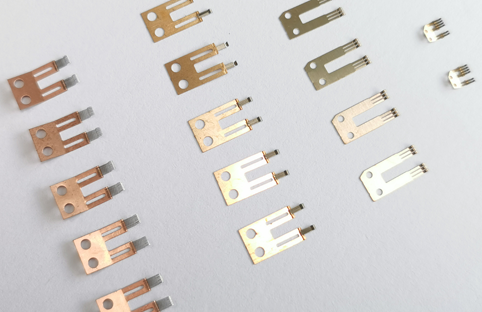

Multiple wires can be joined directly with the spring material to form these so-called Multi-Wire Wipers. Unlike the wipers manufactured by means of stamping technology, Our Multi-Wire Wiper is made by welding up to 35 wires parallel to each other onto a support material. This significantly increases the number of contact points of each contact area. The large number of individual wires of spring-hardened contact materials and their adaptation to variable contact tracks provides an optimal electrical contact. By using corrosion resistant contact materials with electromagnetic shielding, the Multi-Wire Wipers are also suitable for application in corrosive media. Multi-Wire Wipers can be availed in various specifications to suit all application requirements. Customers also can customize the Multi-Wire Wiper according to the relevant application and requirements of the product, All you need to do is just to send us the wiper drawing or specification for production feasibility checking. |

||

|

|||

Multi-Wire Wiper Advantages:

1, Large number of contact points offer excellent contact reliability |

|

Multi-Wire Wiper Applications: |

|

In measurement and control technology as rotating, sliding, and trimming potentiometers (Potentiometer wiper) |

|

|

|