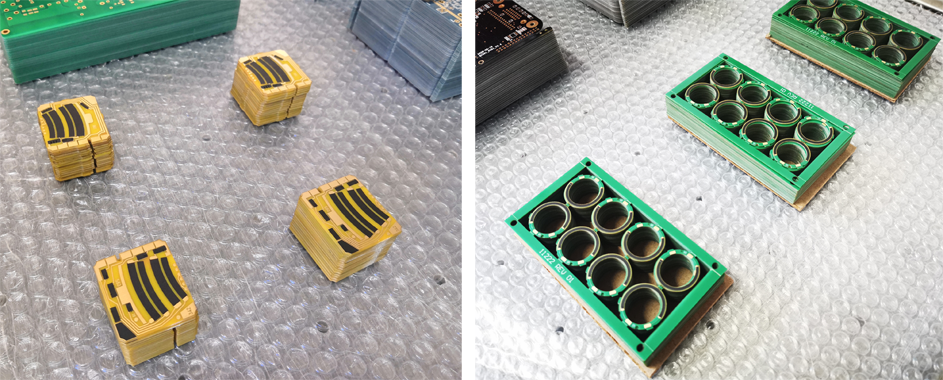

Thick Film Resistor PCB

What is Thick Film Resistor PCB ?

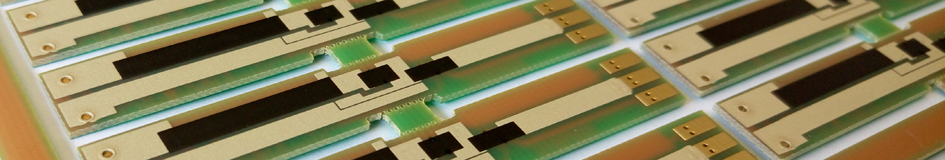

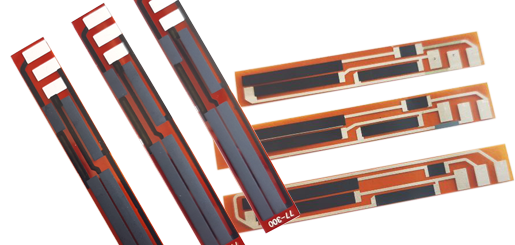

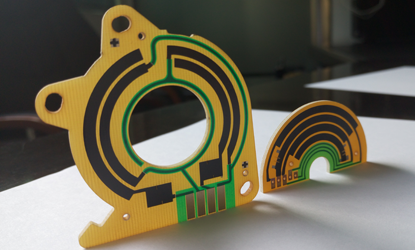

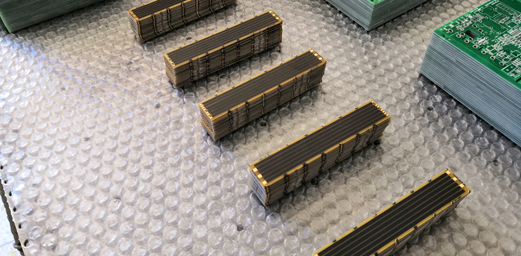

Thick Film Resistors PCB is a new technology to incorporate reliable carbon resistors printing on the printed circuit boards using standard PCB processing. Thus far, The environmental and mechanical testing of Thick Film Resistor PCB processing has also been successful. Continuing to test and formulate higher resistivity values has proved that Thick Film Resistors PCB technology has a future in the embedded passives market. At present, this technology is quite mature that can be printed on a wide range of substrates — from high temperature ceramics to common FR4 materials, or Polyimide (PI) Flex Material. The printed resistor materials (thick film Ink) are based on a novel hydrophobic polyimide resin developed specifically to serve as a polymeric Thick Film Resistors or thin film resistor material. |

|

||||

|

|||||

|

Thick Film Resistor PCB Capability : |

|

Substrate Material : FR4, Ceramic, 96%AL2O3, Polyimide, SUS304. |

| Main Advantages: | |

Excellent high frequency performance |

|

| Typical Applications: | HOME APPLIANCES: |

AUTOMOTIVE: |

|

|

|

|

|