Welcome to Panda PCB Technology Co., Ltd

|

||||||

PANDA PCB GROUP

Panda PCB Technology Co., Ltd., established in 2005 and located in Foshan, China, is a high-tech enterprise specializing in thick film solutions and printed circuit boards integrating research, development, manufacturing, and sales operations. With over 20 years of steady growth, the company has earned the trust of a wide range of customers through advanced technology and high-quality products, becoming a globally recognized supplier of thick film resistor PCBs. Our product range includes thick film resistors, thick film sensors, thick film heaters, and high-performance printed circuit boards, which are widely used in automotive electronics, communication equipment, home appliances, medical electronics, industrial automation, and other fields. With a diverse product offerings, customizable solutions, strict quality control systems, and an international management system, the company has established an outstanding brand reputation in the global thick film resistor market, becoming the preferred partner for leading enterprises across various industries. As a trusted Thick Film Resistor PCB Supplier, Panda PCB Technology Co., Ltd. offers comprehensive solutions that combine cutting-edge design, expert manufacturing, and a robust quality management system. We are committed to delivering durable, cost-effective products that meet our clients' most demanding needs. Our focus on innovation and quality has established us as a globally recognized leader in the thick film resistor PCB supplier, ensuring we provide unrivaled reliability and performance worldwide. |

|

|

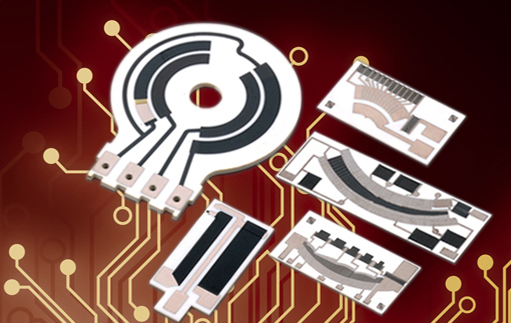

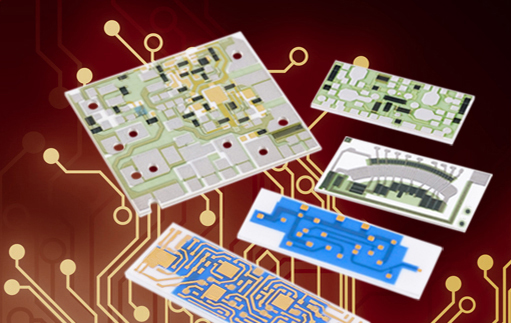

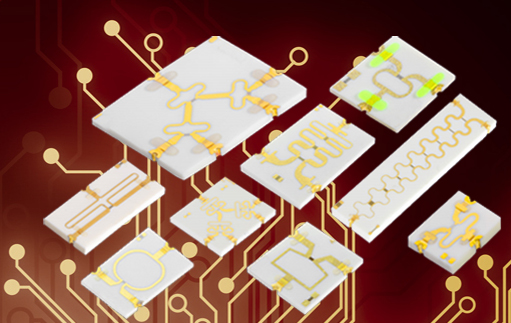

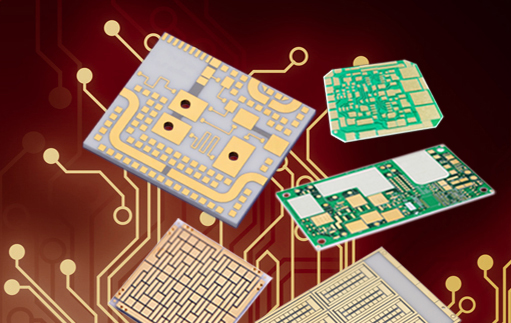

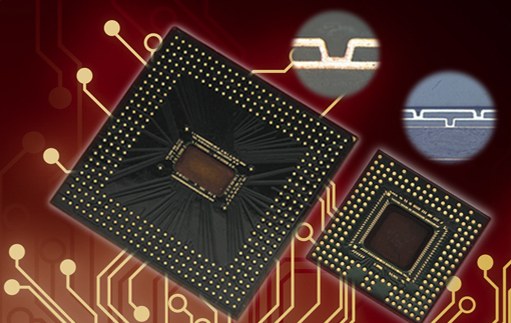

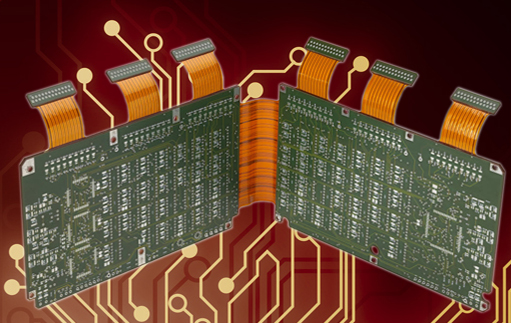

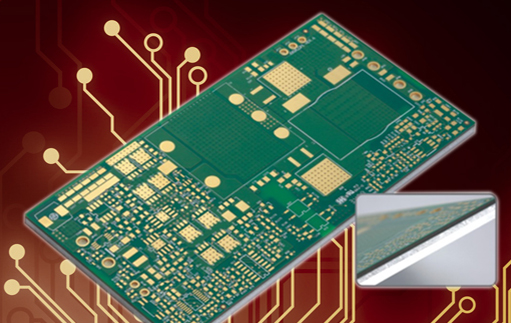

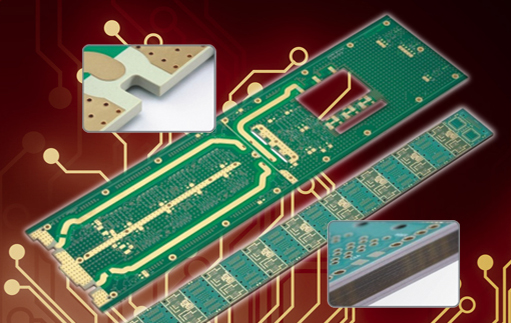

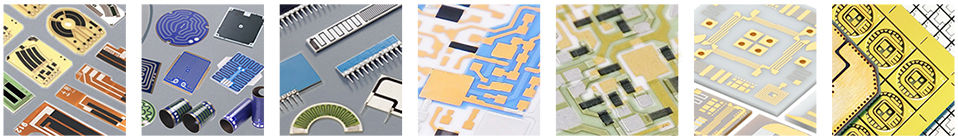

Seizing the historical opportunity brought about by the rapid development of the electronics industry, Panda PCB Group has been a key player in the thick film resistor PCB industry for over 20 years. Adhering to a customer-oriented approach, technology-driven innovation, and a focus on quality, Panda PCB is dedicated to delivering high-quality PCBs. We are particularly committed to advancing our thick film solutions, which are used in various resistors, sensors and heaters. Our product range includes Thick Film Resistor PCBs, Thick Film Sensors, Thick Film Heaters, Thick Film Hybrid Circuits, Thin Film Substrates, Heavy Copper PCBs, Ceramic PCBs, HDI Boards, Flexible Boards, Rigid-Flex PCBs, High-Frequency and High-Speed Boards, Metal Core PCBs (MCPCB), and Thin Film Embedded Resistor PCBs, among others. Additionally, we offer various PCB-related services, such as PCB Layout Design, PCB Reverse Engineering, and Potentiometer Wipers. |

From prototype to mass production, combining the characteristics of product differentiation and high-end features, Panda PCB Group has built intelligent factories, including two major production bases in Foshan and Zhuhai, which follow international management systems, dedicated to advanced manufacturing, technological innovation, and lean production, continuously enhancing our competitiveness and capabilities. Panda PCB Group provides competitive, safe, and reliable products and solutions for customers in high-tech fields such as semiconductors, automotive electronics, communication equipment, medical devices, testing systems, aerospace, home electronics, rail transportation, AI smart terminals, and new energy.

|

|