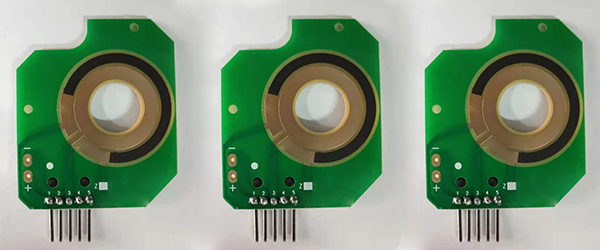

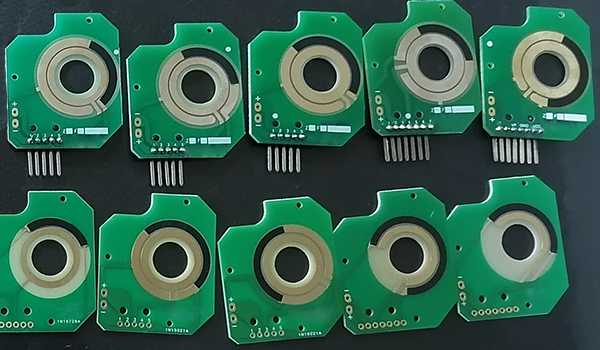

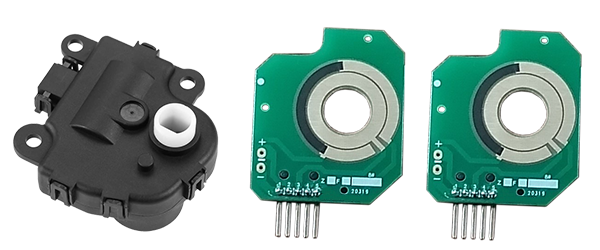

Air Door Actuator PCB

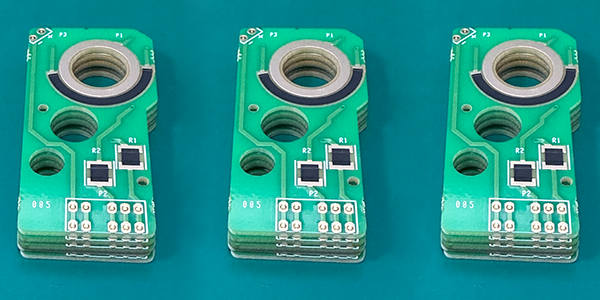

Air Door Actuator PCBs, also known as ADA PCBs, are manufactured using advanced thick-film resistor technology, starting with a screen printing process where variable resistors are applied to the FR4 substrate, followed by a high-temperature sintering process to stabilize the resistor layer and create a precise potentiometer, ensuring long-term stability and reliable performance in automotive HVAC systems, even in high-temperature conditions.

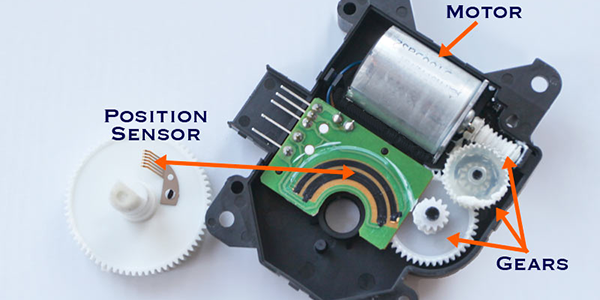

Air Door Actuator PCBs operate based on the principle of adjustable resistance in potentiometers. These PCBs control the angle of the air door switch in the vehicle's HVAC system, which in turn influences the distribution of hot and cold air. As the resistance value of the potentiometer changes in response to control signals, it drives the movement of the air door, allowing precise adjustments to the cabin temperature and airflow. This fine-tuned adjustment ensures a high level of comfort, enabling both drivers and passengers to maintain an optimal environment inside the vehicle.

ADA PCBs are designed to be highly precise, reliable, and resistant to high temperatures. Thanks to the use of thick-film resistor technology, these PCBs maintain stable resistance values even after prolonged use. Their compact structure and durable materials make them suitable for long-term operation in the high-temperature environment of automotive HVAC systems. The integration of a variable resistor within the PCB allows for precise air door adjustments, ensuring the HVAC system meets the required standards for accuracy and stability, ultimately enhancing the user experience.

Key Features of Air Door Actuator PCBs :

1, High Thermal Stability: One of the key advantages of thick-film resistor technology is its ability to withstand high temperatures. Air Door Actuator PCBs are built to endure the extreme heat conditions often encountered in automotive environments, such as engine compartments or direct sunlight exposure, without compromising their functionality. The resistors retain their performance even when subjected to temperature fluctuations, making the PCBs ideal for long-term use in HVAC systems.

2, Durability and Longevity: Thick-film resistors are known for their durability, as they are made by firing the resistive materials at high temperatures onto the PCB. This process results in a robust, wear-resistant layer that maintains its resistance values over time. As a result, Air Door Actuator PCBs exhibit exceptional reliability and can operate efficiently for extended periods, reducing the need for maintenance and repairs in automotive applications.

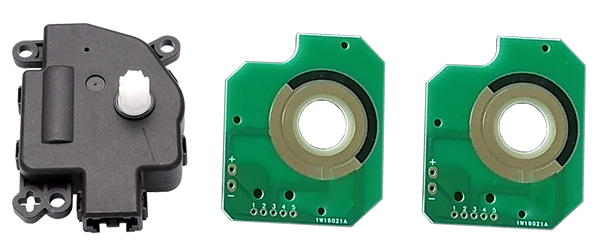

3, Compact Design with High Integration: Thick-film resistor technology allows for compact, highly integrated PCB designs. This is particularly beneficial for Air Door Actuator PCBs, where space within the vehicle is limited. The integration of variable resistors and other components within a single PCB reduces complexity and enhances the system's overall efficiency, making it easier to install and maintain in modern vehicles.

4, Cost-Effectiveness: The production process of thick-film resistors is cost-efficient compared to other resistor technologies, which makes Air Door Actuator PCBs more affordable for mass production in the automotive industry. This helps reduce overall manufacturing costs without compromising on performance or reliability.

5, High Resistance to Environmental Stress: Thick-film resistors used in Air Door Actuator PCBs are highly resistant to environmental stress factors such as humidity, vibration, and corrosive elements, which are common in automotive applications. This makes the PCBs suitable for reliable use in a variety of weather conditions and road environments, ensuring that the vehicle's HVAC system remains functional regardless of external factors.

Air Door Actuator PCBs in Automotive HVAC Systems :

Air Door Actuator PCB (ADA PCB) plays a critical role in the automotive HVAC (Heating, Ventilation, and Air Conditioning) system, responsible for regulating the airflow direction and temperature distribution within the vehicle cabin to ensure the comfort of both the driver and passengers. It adjusts the air door's position to control the flow of hot and cold air, maintaining the ideal temperature in various areas of the cabin.

● Control of Airflow and Temperature Regulation:

The core task of the HVAC system is to regulate the temperature, humidity, and airflow within the vehicle based on internal and external environmental conditions. ADA PCB acts as the executing component in this process. By adjusting the air door's position, ADA accurately controls the direction of airflow, ensuring the effective distribution of hot and cold air. For instance, in demand for cold or warm air, ADA adjusts the air door to ensure optimal airflow and temperature in different areas of the vehicle.

● Coordinated Operation for Optimized Airflow:

ADA PCB controls the precise opening and closing of the air door via electric motors or stepper motors, while the HVAC system adjusts the environment based on real-time data such as temperature, humidity, and air quality. The collaboration between the two ensures precise air distribution within the vehicle. For example, in hot environments, ADA directs cold air, while in colder conditions, ADA distributes warm air, maintaining a comfortable temperature inside the cabin.

● Enhanced Energy Efficiency:

Modern automotive HVAC systems place great emphasis on energy efficiency. ADA PCB optimizes airflow by precisely controlling the air door's position, reducing energy wastage. This is particularly important for electric vehicles (EVs), as an efficient HVAC system reduces the strain on the vehicle’s battery, thus improving overall energy efficiency. Through precise temperature control and airflow management, ADA PCB allows the HVAC system to deliver better comfort with lower energy consumption.

● Increased In-Cabin Comfort:

The precise airflow adjustment capability of ADA PCB is crucial for improving in-cabin comfort. Depending on the number of passengers, their body temperature, and the driving conditions, ADA can flexibly adjust the air door's position to provide a personalized temperature control. For example, some areas of the vehicle may require more cold air, while others need warm air. This level of precise adjustment improves air quality and passenger comfort.

Air Door Actuator PCB (ADA PCB) plays a central role in the automotive HVAC system by precisely controlling the opening and closing of the air door to regulate airflow, temperature distribution, and volume. This enhances the vehicle's comfort, energy efficiency, and temperature control accuracy. With ongoing technological advancements, the control precision and response speed of ADA PCB continue to improve, further optimizing automotive air conditioning systems for better comfort and energy efficiency.

Design Considerations of ADA PCBs :

When designing Air Door Actuator PCBs for automotive HVAC systems, several key considerations need to be addressed to ensure reliability, performance, and efficiency:

● Thermal Resistance: ADA PCBs are exposed to varying temperatures within the vehicle, especially in the HVAC system, which operates in extreme heat and cold. The PCB design must incorporate materials that can withstand high temperatures without degrading, ensuring long-term reliability.

● Mechanical Durability: Air door actuators experience mechanical stress due to vibrations from the vehicle and the continuous motion of the air doors. The PCB must be designed to endure these stresses without failure, using robust materials and connections to ensure consistent performance.

● Moisture and Environmental Protection: Since ADA PCBs are used in environments where moisture, dust, and temperature fluctuations are common (such as in the vehicle’s cabin or engine compartment), protective coatings or conformal coatings are often used to shield the components and ensure proper operation under these conditions.

● Signal Integrity: As ADA PCBs control precision mechanisms such as stepper motors or electric motors, maintaining signal integrity for control signals is critical. Proper design for minimizing noise, interference, and power surges is essential for ensuring accurate movement and timing of the air doors.

● Power Efficiency: With the growing focus on energy efficiency in modern automotive systems, ADA PCBs must be designed to minimize power consumption while still providing precise control. This is especially important in electric vehicles where battery life and energy management are paramount.

● Compact and Lightweight Design: Space and weight are always limited in automotive applications. Therefore, ADA PCBs should be designed to be compact and lightweight while still meeting all functional requirements. Minimizing the size of the PCB and components helps to optimize available space and reduce the overall weight of the vehicle.

● Electromagnetic Compatibility (EMC): ADA PCBs should be designed to minimize electromagnetic interference (EMI) to prevent disruption of other vehicle systems. Proper grounding, shielding, and PCB layout techniques can help reduce EMI and ensure the smooth operation of the HVAC system. By addressing these design considerations, ADA PCBs can deliver reliable and efficient performance within automotive HVAC systems, contributing to a more comfortable and energy-efficient driving experience.

For more information, Please refer to Thick Film Potentiometer PCB.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB