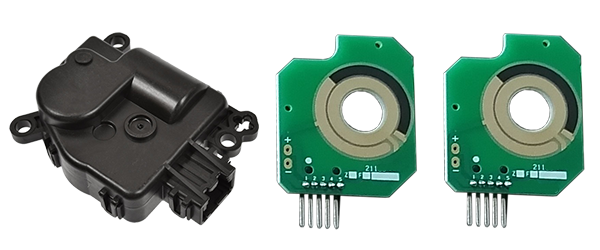

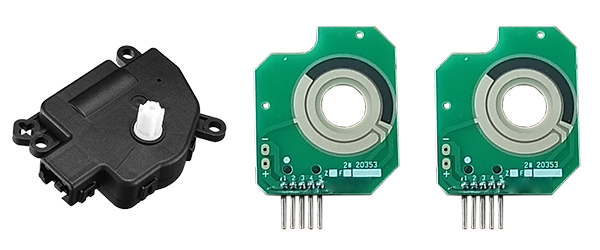

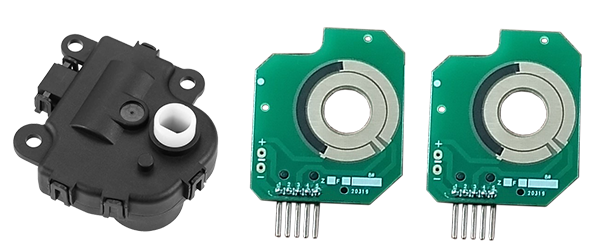

Blend Door Actuator PCB

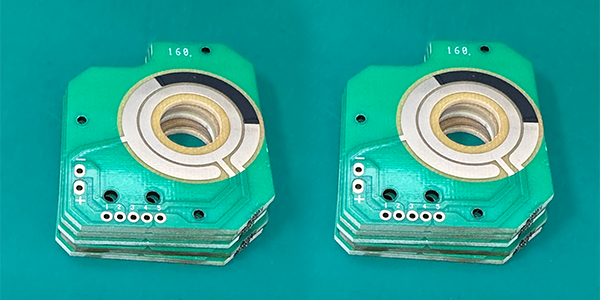

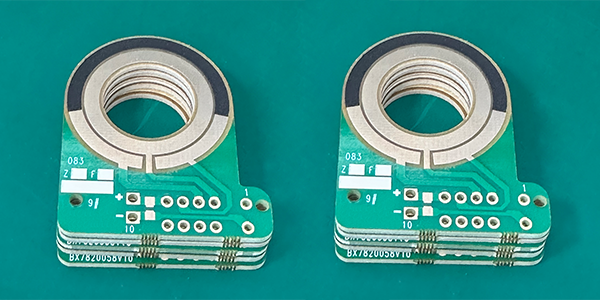

Blend Door Actuator PCBs, also called as Blend Air Door Actuator PCBs are essential components in automotive HVAC systems that regulate cabin temperature through thick-film technology, where a thick-film resistor with an adjustable resistance value is printed onto the PCB, and sintered at high temperature to create a high-precision potentiometer that adjusts the blend door position, regulating the vehicle's interior temperature for a comfortable driving experience.

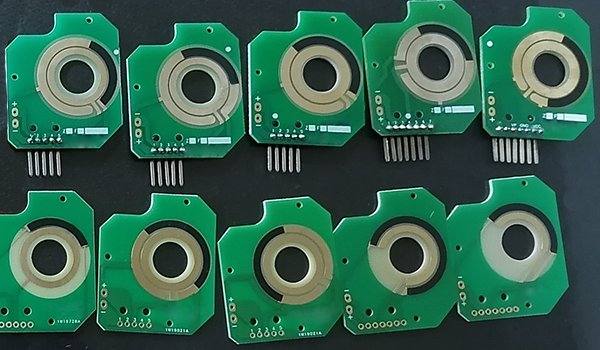

Blend Door Actuator PCBs are manufactured using thick-film resistor technology. The process begins with the precise printing of thick-film resistor material onto the PCB through a silk-screen technique. These resistors are then cured in a high-temperature sintering process, which ensures their accuracy and long-term reliability. This manufacturing method enhances the PCB's electrical performance and durability, enabling it to withstand the harsh conditions inside a vehicle, such as temperature fluctuations and humidity. The high-temperature sintering guarantees the stability of the resistors, ensuring a prolonged lifespan for the PCB.

Blend Air Door Actuator PCBs are characterized by the integration of high-precision variable resistors, offering superior temperature control accuracy and reliability. Compared to traditional mechanical adjustment systems, their electronic adjustment allows for more precise temperature regulation and eliminates the wear-and-tear issues of mechanical components. These PCBs are widely used in modern vehicles, working seamlessly with the vehicle's air conditioning system to improve comfort and control. their robust design provides excellent anti-interference capabilities, making them ideal for the complex electrical environment of vehicles, ensuring stable performance over time.

Advantages of Blend Door Actuator PCBs :

Blend Door Actuator PCB (Printed Circuit Board) is a crucial component used in the climate control system of modern vehicles. It helps regulate the flow of air inside the vehicle by controlling the blend door, which adjusts the mixture of hot and cold air to maintain the desired cabin temperature. Here are some advantages of using PCBs in Blend Door Actuators:

1. Compact and Lightweight: These PCBs are lightweight and compact, which is essential in automotive applications where space and weight are limited. The PCB ensures that the blend door actuator is efficient in its operation without adding unnecessary bulk to the system.

2. Enhanced Durability: Blend Door Actuator PCBs are designed to be robust and can withstand vibrations, temperature fluctuations, and the harsh conditions typically found in a vehicle. The blend door actuator PCB can endure the stresses of daily driving, offering long-lasting performance.

3. Precision Control: These PCBs enable precise control over the actuator's motor, allowing for smooth and accurate positioning of the blend door. This ensures that the cabin temperature is regulated efficiently and that the transition between hot and cold air is seamless.

4. Energy Efficiency: By integrating power management circuits and low-energy components, PCBs help in reducing the overall energy consumption of the actuator. This contributes to better fuel efficiency, an important consideration in the automotive industry.

5. Improved Reliability: The design and manufacturing process of PCBs involve careful consideration of component quality, which enhances the reliability of the actuator. The use of high-quality PCB materials and precise circuit layouts minimizes the chances of failure.

6. Cost-Effectiveness: Blend Door Actuator PCBs allow for mass production and standardization, which reduces the cost of manufacturing blend door actuators. The ability to integrate multiple functions into a single board further reduces the complexity and cost of the system.

7. Versatility: Blend Air Door Actuator PCBs used in blend door actuators can be customized to include additional features such as sensors, feedback loops, or diagnostic functions, improving the overall performance of the HVAC system.

8. Signal Processing: Blend Air Door Actuator PCB enables the integration of signal processing circuits, which help in receiving inputs from the climate control system and adjusting the actuator's position accordingly. This makes the blend door actuator more responsive to user commands and environmental conditions. the use of these PCBs in blend door actuators offers improved performance, durability, and efficiency, all of which are crucial for the optimal functioning of automotive climate control systems.

Applications of Blend Door Actuator PCBs :

Blend Door Actuator PCB (Printed Circuit Board) plays a pivotal role in various systems that require precise control of air flow and temperature regulation, particularly in the automotive industry. Below are the key applications of Blend Door Actuator PCBs:

1. Automotive HVAC Systems (Heating, Ventilation, and Air Conditioning):

● Primary Application: Blend door actuators are predominantly used in the HVAC systems of vehicles. These systems utilize blend door actuators with PCBs to control the flow of air between hot and cold ducts, ensuring that the cabin maintains the desired temperature.

● Function: The PCB enables the actuator to adjust the blend door's position precisely based on signals from the vehicle's climate control system, allowing for seamless temperature management.

2. Multi-Zone Climate Control Systems:

● In modern vehicles with multi-zone climate control (for example, separate temperature controls for the driver and passenger), Blend Door Actuator PCBs are crucial. The PCBs control multiple actuators that adjust the temperature in different parts of the cabin, improving passenger comfort.

● The actuator PCBs enable independent air mixing and distribution for each zone, ensuring efficient and customized climate control for all passengers.

3. Automatic Climate Control:

● For automatic climate control systems, which maintain a set temperature without manual intervention, Blend Door Actuator PCBs work in conjunction with sensors and the climate control unit to adjust the blend door position. This helps in keeping the interior temperature stable according to external weather conditions or cabin preferences.

4. Defrosting and Defogging Systems:

● In addition to temperature control, blend door actuators are used in defrosting and defogging systems. The actuator can control the airflow direction to clear the windshield, windows, and mirrors when fogged or iced.

● The PCB in the actuator ensures precise control of the airflow distribution, directing air to the windshield to prevent fogging or frost accumulation.

5. Electric and Hybrid Vehicles:

● In electric vehicles (EVs) and hybrid vehicles, where energy efficiency is a key concern, Blend Door Actuator PCBs are designed to be energy-efficient while maintaining precise control of the HVAC system. They help in optimizing the climate control performance without unnecessarily consuming power, which is crucial for extending battery life.

6. Luxury and High-End Vehicles:

High-end vehicles and luxury cars often feature advanced HVAC systems with multiple zones and precise climate control. In these vehicles, Blend Door Actuator PCBs ensure that each zone’s temperature and airflow settings are independently controlled, offering premium comfort and user experience.

7. Climate Control in Recreational Vehicles (RVs) and Trucks:

● In larger vehicles like RVs and trucks, Blend Door Actuator PCBs are used to manage the complex climate control systems that regulate air temperature throughout the cabin and cargo area. This is especially important for long-distance travel or for maintaining comfort in the cargo area.

8. Aftermarket and Replacement Parts:

● Blend Door Actuator PCBs are also used in aftermarket products and replacement parts for vehicles. Many vehicles require repairs or upgrades to their HVAC systems over time, and Blend Door Actuator PCBs are critical in ensuring that the actuator works smoothly with new or refurbished climate control systems.

9. Smart Home Applications (HVAC Systems):

● Although primarily used in vehicles, Blend Door Actuator PCBs are also finding applications in smart home HVAC systems. In homes with zoned HVAC systems, similar actuator technology is employed to regulate airflow and temperature control across different rooms or zones, enhancing energy efficiency and comfort.

10. Industrial and Commercial HVAC:

● In industrial and commercial settings, large HVAC systems often use similar technology for air distribution control. Blend door actuators with PCBs can be used to direct air to specific areas, optimize energy consumption, and improve air quality in large facilities or warehouses.

11. Environmental Testing and Research Equipment:

● Blend Door Actuator PCBs are sometimes integrated into environmental chambers and research equipment where precise control over airflow and temperature is necessary. These applications may include testing electronic equipment or researching climate effects.

12. Agricultural Equipment:

● In agricultural machinery (such as tractors or harvesters), Blend Door Actuator PCBs can help control cabin climate. This ensures that operators are comfortable during long working hours, regardless of external weather conditions.

Blend Door Actuator PCB in Automotive HVAC Systems :

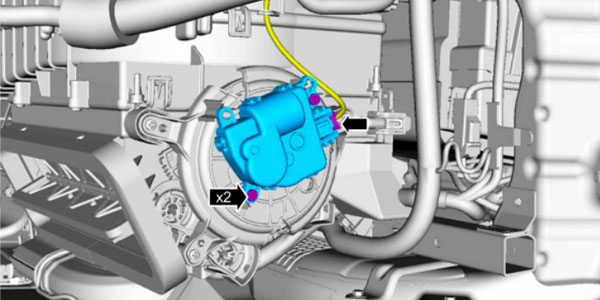

Blend Door Actuator PCBs are key components in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems. They work closely with the vehicle's air conditioning system to help control the cabin temperature and airflow, improving passenger comfort.

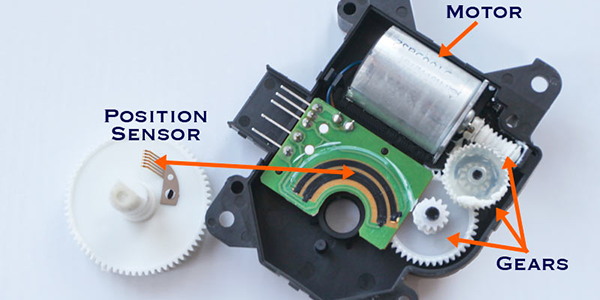

1, Working Principle:

In an HVAC system, temperature control is typically managed by the "Blend Door," which is a mechanical or electronic component that adjusts the temperature of the air entering the cabin. The Blend Door Actuator is responsible for adjusting the position of these "Blend Doors" to control the mixture of cold and warm air, ensuring a comfortable cabin temperature.

2, Role of Blend Door Actuator PCBs:

● Electrical Signal Transmission: The Blend Door Actuator PCBs contain circuit components that receive electronic signals from the HVAC system (usually sent by the vehicle's onboard computer or temperature control panel) to drive a motor that adjusts the position of the Blend Door.

● Precise Control: The sensors and control circuits within the PCB ensure that the actuator adjusts the position of the door precisely. This allows the driver to set the desired temperature through the HVAC panel, and the system automatically adjusts the air mix between hot and cold air.

● Feedback System: In many modern vehicles, the Blend Door Actuator is equipped with a feedback mechanism, using sensors to monitor the door's position in real-time to ensure proper functioning. If a malfunction occurs, the system can alert the driver through the vehicle's diagnostic tools.

3, Coordination:

Blend Door Actuator and PCBs work together with other temperature control components in the vehicle to maintain consistent cabin temperature. The PCBs receive signals from the temperature control panel and drive the motor to adjust the Blend Door's position. Integrated with other systems (such as the cooling system, heating system, and fan control), the entire HVAC system automatically adjusts based on internal and external environmental changes to ensure a comfortable cabin environment.

Blend Door Actuator PCBs play a crucial role in automotive HVAC systems by precisely adjusting the position of the Blend Door through electrical control signals, helping the driver maintain a comfortable cabin temperature. They work in coordination with other systems to ensure that the entire air conditioning system operates efficiently and stably.

For more information, Please refer to Thick Film Potentiometer PCB.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB