High Energy Thick Film Ceramic Resistors

What's High Energy Thick Film Ceramic Resistors?

|

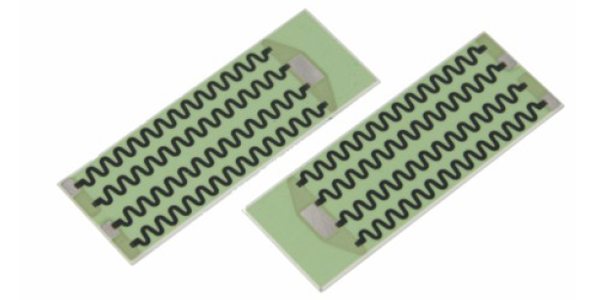

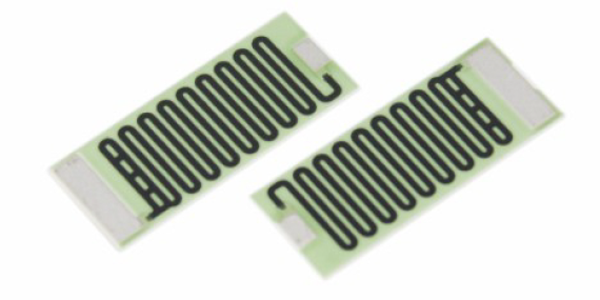

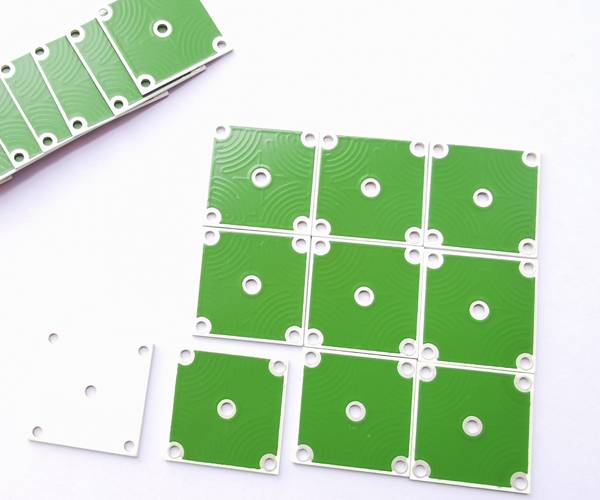

High Energy Thick Film Ceramic Resistors allows simple, efficient resistor designs that enable the designer to minimize the resistor package size while providing the required performance and reliability. High Energy Thick Film Ceramic Resistors offers the user the benefits of non-inductive performance and high power density. They provide the impulse energy capability normally associated with wirewound or composition resistors. Doublesided screen printing of pulse-tolerant thick film resistor, coupled with a sophisticated scan-cut laser trimming process, maximize the energy withstanding capabilities. High Energy Thick Film Ceramic Resistors also calls Power Chip Thick Film Ceramic Resistors, It is a new technology to print the thick film resistor on the ceramic substrate, with high performances of High-Temp Terminal Construction, Wide Resistance Range, Low Inductance (50nH100nH), High Power Density, PC-mountable, and Easy to install etc. High Energy Thick Film Ceramic Resistors can be manufactured in many geometries and sizes, from fractional watts to kilowatts. Design requirements for custom sizes, surface mount, or special footprints can be met easily. High Energy Thick Film Ceramic Resistors are ideal for a wide range of requirements in equipment such as radar, motor drives, broadcast transmitters, RF amplifiers, semiconductor process, power conditioning, xray, lasers, medical defibrillators, and energy research. Specification: Substrate: Alumina High Energy Thick Film Ceramic Resistors Features: ◆ resistance range: 10 Ω ~ 1000m Ω ◆ allowable deviation: ± 1% ~ ± 10% ◆ temperature coefficient: minimum ± 50ppm (25 ℃ ~ 105 ℃) ◆ insulation withstand voltage: > 1000VDC ◆ insulation resistance: ≥ 10g Ω ◆ working temperature range: - 55 ℃ ~ + 225 ℃ ◆ maximum working voltage: 48kvdc ◆ inductance: non inductive ◆ connectors: tinned iron cap ◆ resistance installation: Welding ◆ overload: 5p value does not exceed 1.5umax5s, Δ R≤±0.2%R ◆ service life: rated power 1000h, Δ R≤±0.5%R ◆ steady state damp heat: mil-std-202, method 103, condition D, Δ R≤±0.4%R ◆ thermal shock: mil-std-202, method 107, condition C, Δ R≤±0.2%R Applications: Motor drive circuits Snubber circuits Bleeder Capacitor charge/discharge High-frequency circuits Impulse generators High-voltage circuits X-ray equipment High voltage power supplies Laser/Imaging equipment Capacitor charge/discharge RF dummy loads Dynamic braking Transformer protection For more information ,Please refer to "Thick-Film-Hybrid-Circuit" |

|

|

|

|

|