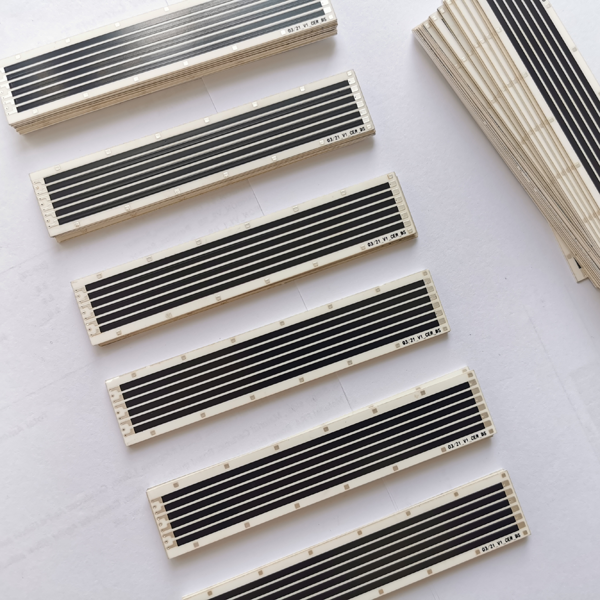

Linear Position Sensors Ceramic PCB

What's Linear Position Sensors Ceramic PCB ?

|

Linear Position Sensors Ceramic PCB also calls Linear Position Sensors Thick Film Ceramic PCB is to incorporate reliable carbon resistors printing on the Ceramic using standard PCB processing. The printed resistor materials are based on a novel hydrophobic polyimide resin developed specifically to serve as a polymeric thick film resistors or thin film resistor material. At present, Linear Position Sensors Ceramic PCB technology is quite mature,thick film inks can be printed on a wide range of substrates — from high temperature ceramics to common FR4 PCB materials,or Polyimide (PI) Flex PCB Material. 1,Ceramic Substrate can be 96% or 98% Alumina (Al2O3) or Beryllium Oxide (BeO), thickness range: 0.25, 0.38, 0.50mm, 0.635mm (default thickness), 0.76mm, 1.0mm. Thicker thickness such as 1.6mm or 2.0mm can be customized too. 2, Conductor layer materail is silver palladium, gold palladium, or Mo/Mu+Ni (for Ozone). 3, Thickness of conductor >= 10 miron (um), and Max can be 20 micron (0.02mm). 5, Ceramic Resistive Position Sensor pcb's Tolerance for final trace layout will be +/-10%. 6, Both gold and silver palladium is workable for gold-wire bonding, but customer need to mention that so that we will use special silver palladium which is suitable for that artwork. 7, Gold palladium is much more expensive than silver, about 10~20 times higher. 8, More different resistor value on the same board, more expensive the board will be. 9, Normally layers of Linear Position Sensors Ceramic PCB are 1L and 2L (with plated through hole (PTH), and plated material is the same like the one used for conductor). 10, Soldermask is also available upon request, working temperature >500 C, and color is semi-transparent. Appilcation:Automotive sensor, industrial sensor, automatic sensor SPEC: Resistane Value : 10M ohm +/-10% (Customizable) Operating temperature range: 120-180℃ Working voltage : > 30KV (AC) Dielectric strength : >1250Vrmas/50Hz/1min For more information , Please refer to "Thick Film Ceramic PCB" |

|

|

|